digital-services

March 28,2025 • 4 min read

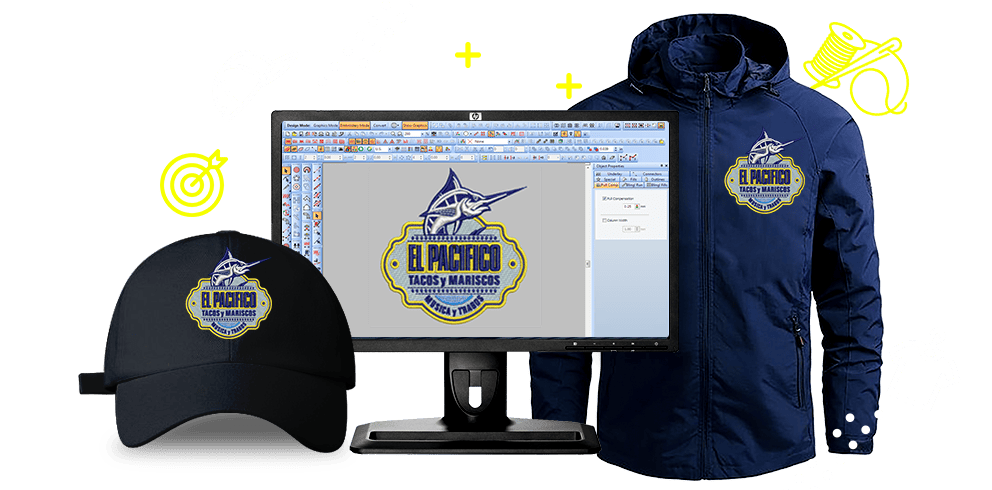

Precision Logo Digitizing for Embroidery Machines

Understanding Precision Logo Digitizing

Precision logo digitizing is an essential process in the embroidery industry, ensuring high-quality, detailed, and accurate embroidery designs. By converting logos into a stitch file, embroidery machines can replicate intricate designs with sharp precision.

What Is Logo Digitizing?

Logo digitizing services is the process of converting a traditional logo or artwork into a digital embroidery format. This file contains stitch commands that guide embroidery machines in creating an exact replica of the design on fabric.

How It Works

A specialized software, such as Wilcom, Pulse, or Hatch, is used to manually map out every stitch. The digitizer assigns stitch types, directions, and densities to ensure a clean, high-quality finish.

Importance of Precision

Precision in logo digitizing ensures clarity, especially for small details, lettering, and complex designs. A well-digitized logo prevents issues such as thread breaks, misalignment, and poor readability.

The Process of Logo Digitizing for Embroidery

Converting Designs into Stitch Files

A skilled digitizer imports the logo into digitizing software, manually tracing elements to create a structured stitch pattern. Different stitch types, such as satin, fill, or run stitches, are used to match the logo’s complexity.

Testing and Adjustments

Once digitized, the design is tested on fabric to assess stitch accuracy. Adjustments are made to improve stitch density, underlay, and pull compensation for the best results.

Finalizing the Embroidery File

After refining the design, the final stitch file is exported in formats like DST, PES, or EXP, ready for embroidery machines.

Factors Affecting Precision in Logo Digitizing

Stitch Types and Their Importance

Different elements of a logo require specific stitch types:

- Satin Stitch for text and outlines

- Fill Stitch for large areas

- Run Stitch for fine details

Fabric Selection and Impact on Embroidery

The type of fabric affects how the logo appears. Stretchy fabrics need more underlay stitching, while thick materials require adjusted stitch densities.

Thread Quality and Color Matching

High-quality threads and accurate color matching ensure a professional finish. Polyester, rayon, or cotton threads contribute to the durability of the embroidery.

Benefits of High-Quality Logo Digitizing

Professional and Clean Embroidery

A well-digitized logo ensures that embroidery looks crisp, professional, and consistent across various materials.

Faster Production Time

Properly digitized designs reduce machine errors and thread breaks, increasing embroidery efficiency and speed.

Cost Efficiency and Reduced Waste

Precision in digitizing minimizes wasted thread, fabric, and production time, leading to overall cost savings.

Common Mistakes in Logo Digitizing

Poor Stitch Density Management

Too many stitches can cause fabric puckering, while too few can result in gaps in the design.

Incorrect Underlay Usage

Underlay stitches stabilize fabric and improve the final look. Using the wrong type can affect design clarity.

Neglecting Pull Compensation

Pull compensation accounts for fabric stretch during embroidery, preventing distortion of fine details.

Choosing the Right Logo Digitizing Service

Experience and Expertise

Look for services with skilled digitizers who understand different embroidery techniques and fabrics.

Quality Samples and Portfolio

A reputable digitizing service should provide a portfolio showcasing past work and embroidery samples.

Turnaround Time and Customer Support

Fast delivery and responsive customer service are key factors when choosing a digitizing provider.

The Future of Logo Digitizing for Embroidery Machines

AI and Automation in Digitizing

Artificial intelligence is improving digitizing software, allowing for quicker and more accurate conversions.

3D Puff and Specialty Stitching

Innovative techniques like 3D puff embroidery add depth and texture, enhancing logo designs.

Eco-Friendly Digitizing Solutions

Sustainable embroidery materials and digitizing techniques are becoming more popular, reducing environmental impact.

Conclusion

Precision logo digitizing is crucial for high-quality embroidery results. By choosing the right stitch types, fabric considerations, and expert digitizing services, businesses can achieve professional-looking embroidered logos with efficiency and accuracy. As technology advances, the digitizing industry continues to evolve, offering even more precision and creative possibilities in embroidery.

Digitizing Buddy Details

User Profile

- Full name

- Digitizing Buddy

- Email address

- digitizingbuddy2@gmail.com

- Join Date

- 2025-03-28

- State

- City

- Pincode

- Address

- Follow us on Facebook

- Follow us on Twitter

- Website Name

- Bio